ShopDreamUp AI ArtDreamUp

Deviation Actions

= Part II: PVC Bows=

Sections:

- Foreword

- Anatomy of the Bow

- Emergency PVC Bow

- Basics of Archery Shooting

- Enhanced PVC Bow

- The Art of Fletching

Foreword

Over the millennia, the choice materials for a bow have span from wood, steel, fiberglass, and composite plastics. Their function are the same, to store energy from an archer's muscles, and release it onto an arrow. A bow’s limbs must be made from materials that are both elastic and strong.

While simple, a good bow must be shaped properly and meticulous, so that its draw is smooth and balanced. Traditionally, a bowyer would select a long piece of wood, called a stave, that has a straight, parallel grain and is knot-free. By parallel, it means the grain runs straight from tip to tip, to ensure tension is applied to the wood in the right direction. Knots are mineral cysts that grow inside a tree, and are detriment to the uniformity and durability of a wood stave, so must be avoided at all cost. Staves are usually cut from saplings (trunks of young trees) or split from larger trunks - from trees like osage, red oak, maple, yew, ash, and any other strong hardwood.

Once a proper stave is chosen, the bowyer uses a planer or drawknife to shape each limb to a taper. From the center of the stave, the thickness decrease towards each tip. This taper insures all parts of the stave bends equally, giving a uniform curve to the bow when strung and drawn. Without this taper, all the bending would be concentrated in the middle of the stave, making for a rougher draw and increasing the likelihood of the bow breaking. A bowyer shaves off wood bit by bit with his tools, ensuring that each limb is equally tapered.

Click on pictures above for more detailed explanation.

Once the taper is done, notches are cut at the tips, but that is not the end to the process. The bow is fitted with a long bow string and put on a tiller. A tiller holds a bow in place and has teethed rack where the bowyer can draw and hold the bow down while he or she visibly inspects the curve of the bow. Any points of imbalance or unevenness can be fixed by removing more wood.

The entire process takes at minimum a whole day for a bow. And that's not including the time to season and dry a new stave cut from tree. Making a proper bow from wood is a lengthy affair, and in the chaos and scurry of an outbreak, a survivor may not have the time or opportunity. Not to mention, the tools of a bowyer are rarely possessed by the typical American or European metropolitan/suburban dweller in this day and age of post-industrial consumerism. For the majority of survivors not blessed with a workshop full of tools, a different material other than wood must be sought for his or her bow.

It might come as a surprise to some that the most readily available material for bow can be found in the plumbing section of your local hardware store. PVC pipes, often use for sprinkler systems or outdoor hot tubs, has a tensile strength and properties similar to bow-grade wood. Unlike wood, you'll find a finished, homogenous synthetic material that’s ready to work with in PVC. PVC can be flexed in good amounts without breaking, waterproof, and it is easily cut by hand. As a thermoplastic, PVC becomes malleable when heated, and can be shaped into a variety of forms. Most important of all, it is cheap. PVC piping would probably be last on the list of items targeted by looters, and even then you can salvage usable lengths from abandoned homes or construction sites.

The PVC bow was introduced into prominence by a Hawaiian resident known by his web alias, the Backyard Bowyer. He wrote a book about his methods of PVC bow construction and demonstrated his various techniques and creations on a Youtube channel. My instructions are mostly based on his techniques. Feel free to look him up.

Anatomy of the Bow

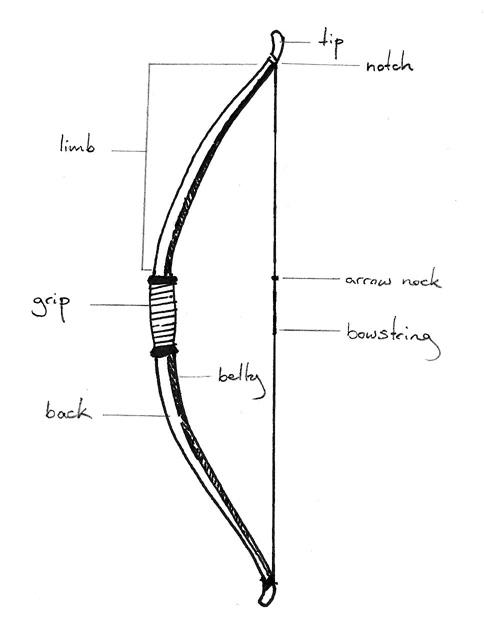

Before we start making or even using a bow, one must learn its parts. Below is an illustration of the terminology you should know and remember as both an archer and bowyer.

On most self bows, you would notice a reversed curve at the tips. This is call a reflex or recurve. A reflex increases the draw weight of the limbs, and smooths out arrow acceleration*. Modern compound bows don't have recurved limbs, as their cams and pulleys serve the function of a reflex.

Tidbit Corner: Arrow Acceleration*When the bowstring and arrow is released at full draw length, it experiences maximum acceleration. But as the limbs move forward, the force they exert decreases, and the bowstring slows down. Sometimes, an arrow would actually travel faster than the bowstring, and come off before full acceleration by the bow. Arrow nocks are there to prevent this, but the arrow's speed is reduced. A recurved bow gets around this problem by using a reflex, which acts as a lever to boost the movement of the limbs midway through the arrow's acceleration, hence making for a more uniform and smooth "push" on the arrow. Any bow that is reflexed hence gains better performance.

To "draw" refers to pulling the arrow back on the string. Release or firing of the arrow is referred to as "loose". To "nock" is to put an arrow on the bow. Draw weight refers to the force acting on the bowstring when fully drawn, measured in pounds and denoted by a # and a number. It is used to gauge the power of a bow. A #40 draw weight is the minimum for hunting in most places. Draw length is the distance you can pull the arrow back on the string, which also determines how long your arrows need to be. The draw weight of a bow is dependent on the draw length of each archer, a longer draw length would give a higher draw weight. Later on, instructions on how to shoot a bow would be provided.

An arrow has four main parts. The shaft is the main body, or the "stick" part of the arrow. It can be made from wood, bamboo, reeds, aluminum, and more commonly these days, carbon fiber. The nock is a slot at the end of an arrow that pinches the bowstring and helps hold it in place as the archer draws*. The fletching or vanes, are aerodynamic fins which stabilizes an arrow in flight, ensuring it flies straight. They are traditionally made of feathers, but pretty much anything can made into good fletching, including duct tape. The arrowhead is the business end of the arrow. There are endless varieties of heads for arrows, from simple point heads, broad heads that increase bleeding, blunt heads meant to stun or hunt birds, to barbed heads for fishing or causing tantalizing wounds. They can be made from steel, glass, flint, or simply sharpened from the shaft itself.

Tidbit Corner: No Pinching!*Contrary what some of us have done as children with toy bows, proper bows are not drawn by pinching and pulling back the arrow, but instead by drawing the string. Never attempt to draw the bow by pinching the arrow; that's what the nock is for. Unless you have the finger strength of a chimpanzee, you would not be able to pull the bow to full draw that way, and would probably pose a danger to all and everything around you, including yourself!

A bow with an offset arrow shelf tends to more accurate than an arrow-on-grip bow, since an arrow set on a grip would be aimed slightly off to the side, resulting in a phenomenon known as Archer's Paradox. An offset arrow shelf does not need to compensate for archer's paradox and can be held vertically straight, ensuring the best accuracy.

Simple, Emergency PVC Bow

Now we start...

You are on the move, the zombie outbreak is in the process of devastating your little gunless Canadian town, and you need a ranged weapon quick. An improvised PVC pipe bow is just what you need. This is the down-and-dirty version of PVC bows; no heat flattening, no reflex, no takedown ability, pretty much just a bent plastic pipe with a string tied to it. Its one step up from just stringing a random tree branch you found on the ground, but it would be strong enough to "hurt" if you need it to.

With some practice, it would come in handy if you’re attacked by looters or other unsavvy opportunists, maybe even hunt with it while you’re hiding in the woods. It might not be accurate enough for taking headshots unless you’re really close, so use it sparingly when facing Zeds - use a melee weapon instead.

Tools and Materials at a Glance:

- Schedule 40 PVC pipe (3/4" or 1" diameter)

- High strength cord (polypropylene, hemp, nylon, dacron, etc.)

- Saw (hacksaw or carpenter's saw)

- Tape (duct tape, masking tape, or electrical tape)

- Scissors/Utility Knife

- Wood Dowels/ Bamboo Sticks, 32 inch minimal length

Optional

- Household 18 gage copper wiring

- Steel wire

- Ruler/Measuring Tape

- Drill

- Power Saw

- Vice / Clamps

- Scrap Plastic (food containers, pop bottles, etc, blister packs, etc.)

- An extra hand

---

a) First, you would need to Get yourself a ¾ inch or 1 inch PVC pipe. You can find in any hardware store such as Home Depot or Lowes. The thicker the pipe, the more draw weight you would get from it. Use ¾ inch if you have doubts about your upper body strength. Make sure the pipe is pressure rated (should be NSF-PW on label), not cellular cored or DWV, which are much thinner and hence useless for our purposes.

b) Grab some polypropylene cord or mason string for your bowstring, preferably rated for a working load above 100 lbs (it would say on the package). You want something strong, but also thin enough to nock arrows to. If you can't find thin, you can get a twisted cord (NOT BRAIDED), and unravel it into a thinner cord. Home Depot has a whole section near hardware that sells ropes and cord, I personally found mine at the Dollarama. The stronger the better; you do not want to use your grandmother’s craft jute string! It would snap and break before you even have a chance to shoot your bow.

c) You would now need some shafts for your arrows. Poplar dowels make decent shafts, and again you can find them at your hardware store most of the time in various sizes. You want them at least 32 inches in length, and 3/8 to 7/16 inch diameter, the thicker the better. If you can't get dowels, you can also use lengths of straight bamboo, pond reeds, hollow aluminum tubes, or anything straight and light enough for arrows. You can also skip the hassle entirely and go look for arrows at the sporting or hunting store. But how I see it, if you had such a store to go to, you won't be needing the PVC bow in the first place right?

Grab a saw (hacksaw or fine tooth carpenter saw) if you don’t already have one, and some quality duct tape for good measure.

STEP 1.5: Get to safe location to build.

---Quickly make your way back home or hideout, avoiding zombies and individuals named Andrea. If you’re returning to your family residence, I would grab a shovel from the garage or yard before I head on inside. Some of your love ones might have return home as a member of the undead; and it is your duty to dispatch them with pure prejudice. Just picture the time your mother threw your Pokemon cards into the washer, or that time when your brother thought it be funny to switch your shampoo with craft glue. I keep track of little things like that for each of my family members, on the off chance I need to put down any of them when they turn. You should as well.

Once you have smash their infected brains in, proceed upstairs and lock yourself behind your bedroom door. Put a chair against the door knob for extra measure. Now that you’re (relatively) safe inside your room, it’s time to start assembling your PVC bow, pronto.

Tidbit Corner: Melee and YouA melee weapon is a must during a zombie outbreak - you don't need ammo for one, and you're bound to need it when zombies box you in at close quarters. Use it to push away zeds and keep biters at a distance. You'll want something sturdy and with good reach. Blunt weapons are a good choice, something like a bat or lead pipe can cave in a skull when proper force is applied, while limiting fluid transfer during a fight. Chopping weapons are not the best, as sharp edges present a greater risk of you hurting yourself, and slashing and gashing at infectious flesh poses a great danger of contamination through wounds and accidental ingestion. A long shaft with a sharp point, like a fireplace poker or spear, are great for thrusting attacks aimed at puncturing the skull. A thrusting weapon helps to conserve energy and good for use in tight spaces where swinging is prohibited. Keep your melee weapon clean and sanitized, wipe it down and dunk it in fire or boiling water after use when possible. You don't want to risk becoming one of the undead just because your hand caught a splinter on the wooden handle of your weapon that was covered in zombie gore.

STEP 2: Cutting to Length

You need to cut the PVC pipe to length with your saw. Cut it to 56 to 62 inches long – The length is suppose to reflect your height, so I recommend cutting it to the height of your shoulder. A longer pipe also gives a lower draw weight, so cut it longer if you want to make shooting the bow easier for yourself.

When you cut PVC, you get these fuzzy shavings that statically cling to everything. Lay some newspaper or tarp under the pipe as you cut it for an easier clean up. I personally keep the vacuum cleaner nearby when I'm cutting anything. I like to think once things go down the crapper, being tidy would be one of the things separating us from the mindless walking dead.

Once you done cutting, you will have the stave for your bow.

STEP 3: Cutting Notches

Second step is to cut notches on either ends of your stave for the bowstring. Use a pencil or sharpie to mark a line across the pipe, 1/2 inch away from each ends of the pipe. Using your saw, cut a slot one-third of the way into the pipe diameter at the marked spot. making sure the slots line up and wide enough to fit your polypropylene cord in.

NOTE: I know I drew the slots perfectly square, but you should really make your cuts towards a wedge point. That way, the excess material would come off more easily.

STEP 4: Bowstring

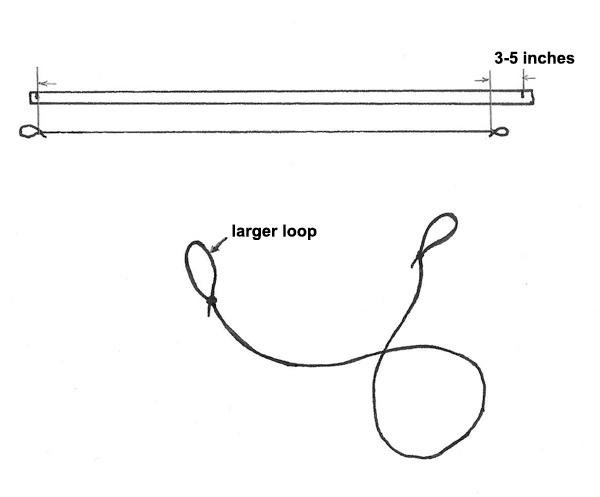

Now prepare your bowstring from the polypropylene cord by tying two loops at each end. The distance between the two loops should be 3-5 inches shorter than the length of your PVC stave. The loops has to big enough to fit over the pipe.

One loop should also be wider than the other. The smaller loop is usually always attached to the bow, and the larger loop is what you lash on every time you string your bow. You should know, if you don’t already, that you never leave a bow strung indefinitely or it would lose its draw. Unstrung your bow every time it’s safe to do.

If your preparing a thick cord for your bow string, snip a little of the end of it and untwist the thinner cord strands making up the larger cord. Tie knots into the ends of your smaller cord to prevent it from unraveling.

STEP 5: Stringing the Bow

Take the smaller loop from your bow string, and slip it over one of the notches on your stave. Make sure its in and tight; secure it with a piece of tape so it doesn’t slip out.

Now comes the hard part. You have to take the other loop, and slip it over the notch on the other side while putting the curved flex to the bow. I use the "step-through" method, which I would present here. Stringing a bow in this manner takes quite a bit of muscle work, and you may need to call on your inner-saiyan for that final push.

Start by slightly spreading your legs. Thread the stave diagonally between your legs. The already looped end should be pressed in front and against one foot. The middle of the stave should be pressed firmly behind your other leg. Grab the upper un-looped end of the stave with your hand and the free loop in the other hand. Now using your leg as a fulcrum, push and pull the stave's end forward, flexing the stave towards your string until you can lash the loop onto the notch. It might take a few times, especially if you chose the monstrous one inch diameter pipe for your bow, but you’ll get it...probably. If you don’t, then that’s an early indicator that your bowstring might be too short. Go to the next step on adjusting your bowstring.

Life of a Zombie Researcher

I remember when I bought my #30 Wildcat recurve, my first ever bow, and I tried to string it the way the shop clerk had shown me (step-through method). I couldn’t do it, so I bought one of those foot stringers and walked out of there looking like a wimp. It’s been several years, and I’ve put on some brawn since then. Now, I string my bows by doing step-through, and that old foot stringer has been lost ever since. Good riddance, the darn thing keeps tangling.

Generally, you want the bowstring long enough to give you a nice gentle curve to your bow, with enough space between the middle of the grip and bowstring, called the brace height. Brace height needs to be wide enough so you can fit your hands on the grip; if its too short, the bowstring would slap your hand or arm after release. But if brace height is too high, you may over stress your bow and make it harder to draw. Brace height should usually be 7 to 9 inches; a good quick way to measure is to have the string match the height of your hand. Adjust your bowstring until you get a good brace height, either by adjust the loop or tying an extra knot to shorten the string. To unstring your bow, do the step-through again, but this time to take off the string loop.

Once you have adjusted the bowstring to your satisfaction, pull back the string to get a feel of its weight (with all fingers, again no pinching!). DO NOT DRY FIRE THE BOW. Dry fire is when you draw the bow and release the string without an arrow. With no arrow, all the concentrated energy in the limbs have nowhere to go, and it would damage your bow irreparably. This includes having a limb snap off and fly towards your face.

STEP 6: Arrow Rest

For an arrow rest, you can take some leftover cordage from making your bowstring, and wrap it around the middle part of your bow into a grip until its thick enough to rest an arrow on. You can also substitute with tape. Position it so that the arrow can sit at the exact center of the bow.

For a more sophisticated approach, you can make an arrow flap rest. An arrow flap is simply a piece of flexible material that subtlety holds the arrow, but flexes out of the way when the feathers on the arrow passes through. With an arrow flap, you don't have to angle your bow to prevent the arrow from falling. For an arrow flap, you can cut and tape a piece of thin card board or plastic on the grip. Make sure it flexes out of the way easily, but is still rigid enough to hold a arrow.

STEP 7: Adding String Nock

A string nock is simply a thick bump in the middle of the bowstring that keeps the arrow from sliding off. Above is a nock made from a piece of tape rolled around the bowstring just above where the arrow should be. You can even just tie a big knot with some string at that spot for a nock.

The arrow nock sits above your arrow to prevent your arrow from sliding up the string via gravity. I like to add another nock below the arrow just for a tighter hold. Also, wrap a layer (not too thick) around the bowstring just below your nock. It would prevent the nock of the arrow from chaffing your string and weakening it.

STEP 8: Arrows!

Your bow is complete! Mind you, this is a very crude bow, and since there is no taper, you would notice that your bow flexes sharply at the middle, while the end of the limbs barely flex at all. You'll also get a good bit of handshock when shooting this bow. Later on, I would instruct on how to further refine a PVC pipe stave with a taper.

Right now, the only thing you're missing is a set of arrows. Arrows are a very time-consuming part of an archer's gear to make. I am going to teach you a very quick, improvised two-vane arrow that can be prepare from wooden dowels mentioned earlier. You can also prepare these from straight lengths of bamboo, an excellent material for arrow shafts found in gardening stores as decor stakes.

Most arrows these days have the triple-vane set up, three vanes set 60 degrees from each other. Without a fletching jig, its going to be very time consuming for you to get your vanes straight and equally spaced at such an odd angle. A two vane fletch, each vane 180 degrees from the other, is much easier to make, and they aren't any worst for accuracy versus triple vanes. Plus, two vanes don't rub against your grip or arrow flap as much - they make for smoother release and so you don't have to repair or replace the vanes as often.

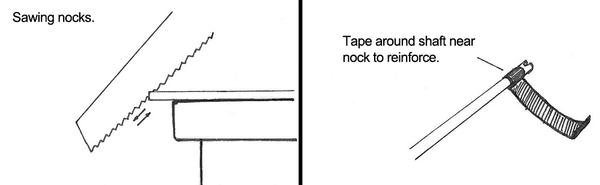

8A. Cutting the nocks.

As mentioned before, you need nocks to help hold your arrow on the string. Usually, that just means cutting a little notch at one end of your shaft. The notch needs to be wide enough to let your bowstring through, but still snug enough to pinch an arrow in place.

There are two ways I like to make my nocks, either a wedge cut or slot cut. A slot cut is the best, because it pinches the bowstring better. A wedge cut is easier to make, and also an optional when your bowstring is too thick for your arrow shaft to make a slot cut, but it would hold looser.

With a wedge-cut, simply mark a triangle cut off with a pencil on the side of the shaft, and start sawing at two angles until the piece comes off. If you only have a hacksaw or hand saw and no other tools, the wedge cut is a good option to do.

A slot cut is a little harder to make, and requires a few more tools at your disposal. If you had a table saw or mitre saw, you can use it to VERY carefully cut a bit material from the shaft to form a slot using the thickness of the saw blade. A slower but more accessible way is to use a drill, make a small hole through the side of the shaft, and saw down the end until the excess comes off. Alternatively, you can use the edge of a metal file to file down the shaft end until you get a slot, but this is no doubt the most time laborious method.

When sawing, start at an angle first for easier cutting, gradually straightening the saw as you cut. It is best if you use a vice or clamp to hold the shaft on a table as you saw your nocks in. If you don't have either of these handy, you can also use a stack of heavy phone books to weigh down the shafts, or tape the shafts down to the table. Pressing the dowels down with your free hand is also doable but it is harder to cut your nocks straight and neat, though I use this method excessively, as it is quick and I don't have to mess with annoying clamps.

Nocks should be around 3/8" deep, or the width of your pinky finger. If you're making wedge-cuts, they should be a little deeper so that they can pinch the bowstring properly. Once the nock is cut, tightly wind some tape, 2-3 times around the the shaft just behind the nock to reinforce it. This is prevents your arrow from splitting, which does happen with wooden arrows as the bowstring basically cuts through the shaft along the grain of the wood.

8B. Cutting shaft to draw length.

As mentioned before, the draw length is the the distance between the nock and grip when the bow is fully drawn. Draw length varies from person to person, ranging from 26 to 32 inches for the average adult. To find your draw length, hold your bow and assume a shooting stance. Rest the shaft on the grip of the bow, and pinch the arrow at the nock between your fingers - one finger above and two fingers below as if you were really drawing to shoot (look at examples below) - and draw the arrow shaft until your hand reaches your cheek or chin. Mark and measure where the arrow stops at the grip, that would be your draw length. Saw all your shafts to proper length, at least four inches more than your draw length.

8C. Making the vanes.

Vanes act on air flow to stabilize your arrow in flight, the same way a fins on a rocket or a rudder on a plane does. You can make vanes from pretty much anything. The critical thing is to make sure your vanes are the all same size and shape as each other and that they are attached neat and straight to your shaft. If the vanes are not the same on one arrow to the next, they would fly differently with every shot, impairing your accuracy as an archer. If your vanes are not straight to the axis of the shaft, they would veer off course; I personally seen one of my early, bad arrows make a 90 degree angle turn when shot.

First choose a material for your vanes. I personally prefer cardstock paper (from queue cards), as they're light, thin, and easy to cut. I laminate them with a layer of duct tape to strengthen and waterproof them. You can also use thin plastic (from containers or bottles), paper, or heavily folded tape (masking and duct tape are best). You'll want a material that can flex, but still rigid enough to hold its shape, or else your vanes would get worn down and bent pretty quick.

Next step is to cut out an aerodynamic vane from the material. Usually, a corner cut off from a rectangular piece is adequate, but there are a variety of shapes you can do, the important thing is to make sure each vane is exactly the same as the others. A good trick to use is to cut out and keep a proof vane, and trace your other vanes from it, getting you an consistent shape every time. I like to cut my proof vanes from sheet aluminum, which last longer and are easier to trace with. Your vanes should around the size of your thumb - too small and they won't do much, too big and they'll induce too much drag.

Cut out two narrow and long pieces of tape, and tape them on each side of a vane, leaving half to tape onto the shaft. Carefully position and tape the vanes down behind the nock, and line it up with the nock. This is important; if they are not lined up with the cut of the nock, the vanes would hit against the grip when the arrow is loosed. Keep the vanes as straight to the axis of the shaft as possible, add more tape if necessary to secure the vanes, and fold over or cut off any excess tape with scissors.

8D. Arrow Point.

Making and attaching the arrowhead (hafting) is perhaps the most difficult and laborious part of fletching an arrow. Arrowheads can be knack out from flint or glass, molded from bronze, or forged from steel. But, unless you have a forge, a fully-furnished workshop, or have been knacking flint for years, the best you can do right now is whittle down the shaft to a pointy end. The result leaves much to be desire, but a sharpen wooden point can still go through flesh and hit vital organs.

Use a knife to put in a sharp point at the free end of the shaft. Rub some white or wood glue onto the point and let it dry to a hard lacquer.

The next step is to take some 18 gage copper wire (the common type used in homes), and wind it around the shaft several times, starting at least 3 inches away from the arrow point; three inches being the minimal depth of body penetration require to hit a major organ. This serves two purposes; one to reinforce the shaft end, and two, as weight to shift the center of gravity forward. A forward center of gravity is required to prevent the arrow from flipping itself backwards in forward flight, hitting the target with the blunt end of the nock instead of the arrow point.

To find the center of gravity, measure the middle point of the arrow's length, and balance the arrow on your finger. If it tilts towards the head of the arrow, than the center of gravity is correctly forward. If it tilts towards the vanes, add more winding to increase the forward weight. You don't need too much forward CoG, as the vanes counteract the effect somewhat.

If you don't have copper wire, you can use tape instead, but it might take a lot more winding since its lighter. Steel wire, waxed cable lace, and rubber bands can also be used, but thick copper wire is the best since its ductile and dense. Use pliers to help get a tighter winding.

You now have a finished arrow, ready to be shot from your bow. Mind you, the wooden point will have a hard time penetrating skull, but it would go through fabric and flesh - against human assailants, it would serve well.

Basics of Archery Shooting

--- It has taken me quite some time to write this piece - its been almost a month since I started, and I suspect I would need another two weeks to finish the rest of the Part II. Since I want to show you guys at least something, I have post the material I written up so far. Please stay tune for the rest of Chapter 1, Part II

Improvised Weaponry: Chapter 1, Bows - Part I

PART I - Bows & the Survivor

=Introduction=

In this chapter, we'll be exploring the viability of bows and arrows, and their method of use, for survivors of a zombie outbreak. Much of the information provided is based upon my own personal knowledge and experience in regard to archery and bows. Later on, I would provide instructions on how to construct and use an improvised PVC bow. This information here is not meant to be exhaustive, or even expert in detail, but instead meant to provide the unacquainted survivor with the basics of archery and how to effectively apply the bow in a zombie outbreak situation. Crossbows would not be includ

Quote of the Day #1

1. It takes skill to kill an armed opponent, but it takes more skill to disarm an armed opponent.

2. Judge a man not by his ability to do but in his ability to restrain.

Featured in Groups

© 2013 - 2024 Ming-Lung

Comments1

Join the community to add your comment. Already a deviant? Log In

Very interesting.